|

MTX-IV

Disassembly Procedure

Brief

instructions on how to disassemble your

MTX transmission.

Updated

02-08-06 ~ Bizzy

|

While the MTX trans isn't

that

complicated, it is a rather

complicated task (for me) to tell someone how to disassemble it. I could show you in 5

minutes. But also

keep in mind that there is an order in

doing things and there is a reason for the order.

Below you will find

illustrations on the disassembly process, however

the responsibility, liability and risk is upon you if you decide to

take your trans apart. In

other words, I assume no responsibility if you

screw something up, lose a part or otherwise can't get the trans put

back together or if

something goes wrong with the trans after you get it put back

together. I also have

not gone into great detail on these instructions, there are not (not

yet anyway)

instructions on how to clean the internals and perform the re-assemble,

so you do this at

your own risk. I will try to finish the whole write-up ASAP,

but it will take time.

If you run into a boggle, feel free to email me

if need be.

Having said that,

here’s some illustrations for you to go by.

|

|

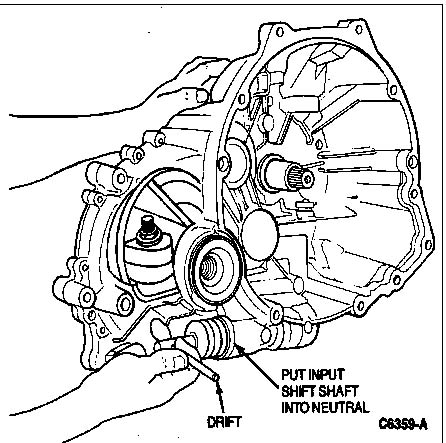

The first thing to

do is

to sit

the trans as positioned in the picture below.

Insert

a drift punch into the hole in the shift shaft and place the trans into

neutral if it

isn’t already and move the trans into the neutral position. This is an important step

in order to make it

easier for the removal of some of the internal parts.

Failure to do so and you risk

damaging the synchros!!

|

|

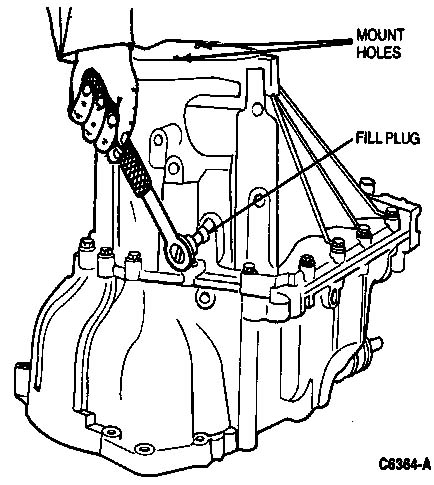

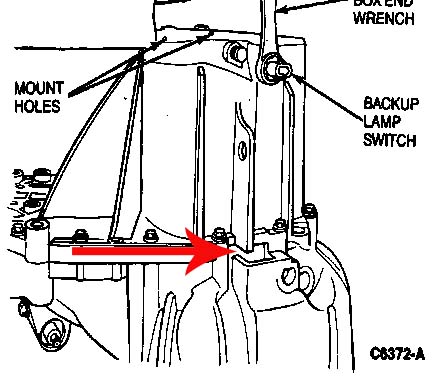

Second thing to do

is

place the

trans on a bench with the bell housing side down.

Prior

to that you can remove the shift fork assembly or not.

To gain access to the internals it is

not an

absolute necessity however with the

fork in place you’ll have to move it out of the way when

removing a couple of the

case bolts. It IS

a good idea to

remove it so you can at least clean the assembly and check your

bushings to make sure they

are good. They're cheap enough and it would be a good idea

to replace them.

You can also remove the backup lamp switch as well. Again,

you don't have

to in order to open the trans up.

Remove

the fill plug by inserting the square end of a 3/8 ratchet into the

plug and loosening as

you would any bolt. Rightsy-tightsy,

leftsy-loosey.

|

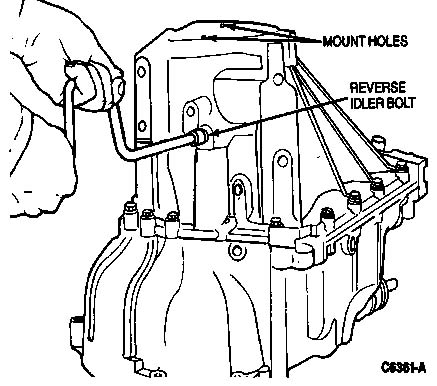

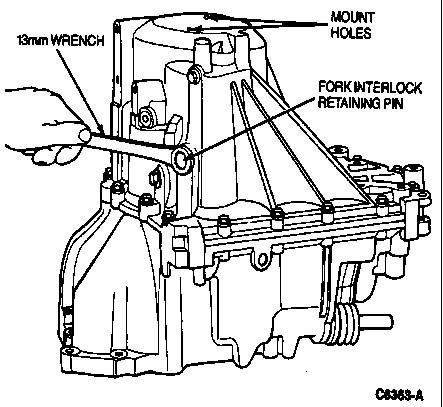

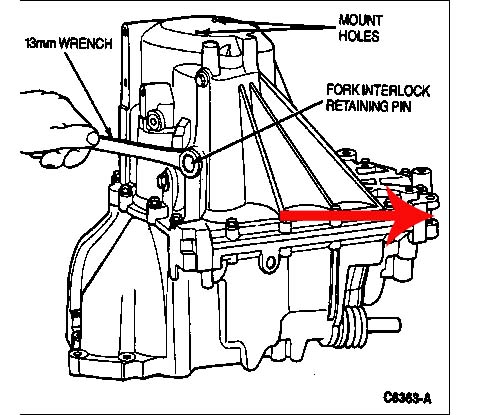

| Remove

the reverse idler retaining bolt and the fork

interlock retaining bolts. LOOSEN (ONLY LOOSEN)

the detent plunger

retaining bolt. It's a good idea to keep a plastic

bag handy to keep all the

bolts together so they don't get lost or misplaced. Do

NOT

completely remove the detent plunger retaining bolt. (Or

do.....but you'll be

soooooorrrry.)

Remove

Remove

Loosen

only

|

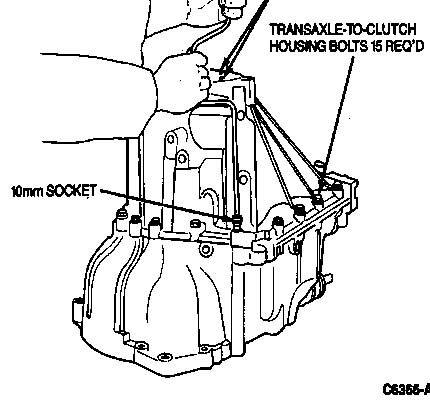

| Now

remove the 15 (sometimes 16) case bolts. Pay

attention if yours only has 15, you'll want to replace them into the

same holes.

|

| Now

it's time to separate the case halves. There

are two spots on the case that can be used for prying, I use the same

tire iron (AKA

"Tranny Tool") to pry the case halves apart. Under NO

circumstances should you insert the tool between the mating surfaces of

the case

halves. Those surfaces must stay true in order to seal

properly. If you

scratch or gouge those surfaces your tranny will leak, so take care

during the separation

process, use only the pry spots in the pics below. NEVER

set a case

half on the ground on those surfaces.

Illustrated below are the areas that are

safe to

pry the case halves apart.

|

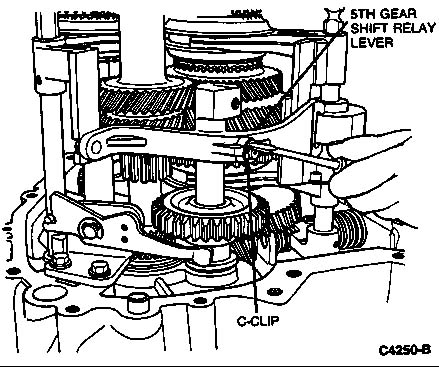

| Locate

the reverse idler gear assembly. Take a

small flat tipped screwdriver and remove the C-clip and set it

aside. Remove the arm

from the assembly. Take the center shaft in one hand and the

gear in the

other. Lift up on the center shaft, once it clears the case

you can remove both the

gear and the shaft. Generally I will reassemble the shaft,

arm and C-clip just to

keep the parts together, the C-clip is easy to lose and that's not a

good thing.

|

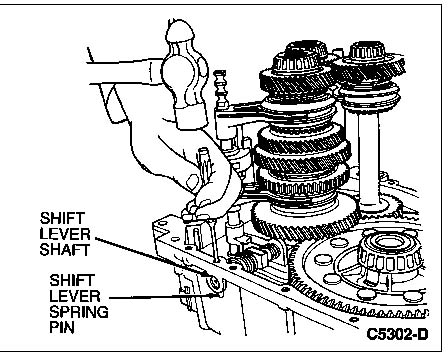

| Next

you need to remove the spring pin that holds the

shift lever spring assembly. Use a drift punch to drive the

pin from the case.

MAKE SURE THE DRIFT PUNCH IS NOT TOO

SMALL!!!!

You do NOT

want to get a punch stuck in the middle of the spring pin, trust me.

|

| Remove

the shift shaft lever assembly. I usually

use an every day tire iron to nudge the center shaft outward a little

bit. Once the

shaft is out of the case enough you can catch the hole in the shaft

with a drift punch or

small screw driver. From there you can manually remove the

shaft. Once the

shaft comes out enough you can catch the 2 springs. Depending

on the mood of the

person who assembled your transmission (or Ford's stock), you may or

may not have 2

springs. It seemed luck of the draw on whether the reverse

kickback spring was

installed or not. There will be at least 1 large spring on

this shaft

however.

*Important note: When removing the

shaft

it is a good idea to put

your finger over the hole in the shift lever assembly.

Sometimes when the shaft is

removed the detent spring will shoot the ball bearing out of the

hole. It doesn't

come out with a lot of force, but you don't want to lose the ball

bearing. Rarely

have I seen this, but it has happened.

Once the shaft assembly is out, remove the

lever

assembly. At this point it's

just sitting there with nothing holding it in place.

|

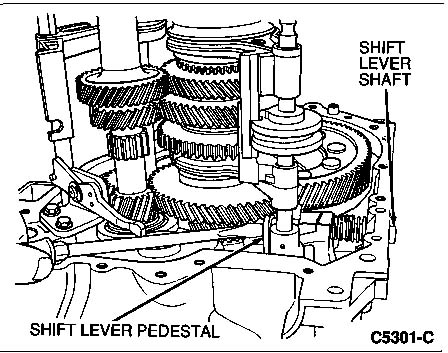

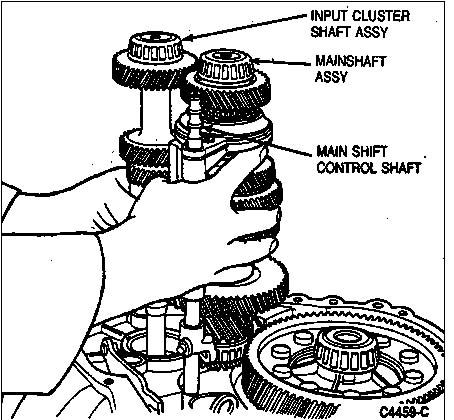

| Now

it's time to remove the main gear shaft assembly,

shift fork and input shaft. Take great care when removing

these parts, they are

heavy and if mis-handled you run the risk of popping a synchro

apart. (Don't drop

them!) With your left hand grasp the shift fork firmly, with

your right grasp the

assembly firmly and as evenly as possible across the entire

assembly. It's a good

idea to put your fingers on the gears rather than the synchro since

they can and will pop

apart. Lift on both the fork and gear assembly and input

shaft to remove them all

at the same time. They're heavy so take care when doing

so. When lifting the

gear shafts, lift straight up until the fork and gear assemblies clear

the case and the

funnel in the case that's under the race for the bearing. The

funnel is made of

plastic and can be damaged if mishandled. Set the gears and

fork aside.

|

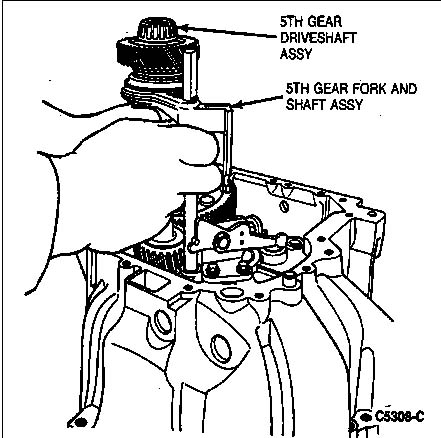

| Remove

the 5th gear shaft assembly and fork. They

lift right out and are easily removed. There is another

plastic funnel under the 5th

gear shaft assembly as well.

|

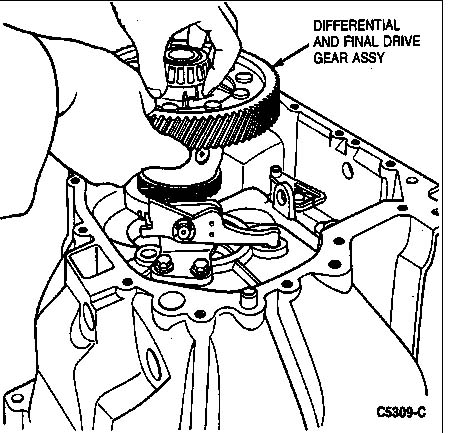

| At

this point you can remove the differential assembly

from the case, it just lifts right up. It's heavy so take

care to not drop it.

|

| Now

is a good time to check the bearings and bearing

races, replace your axle seals, input shaft and shift shaft

seals. Remember that if

nothing else, you should at least replace your input shaft seal since

it is the only one

that can't be done from the outside. Now would also a good

time to install a drain

plug as well. I never did enjoy doing those while the trans

is installed on the

car, MUCH easier with it on a table. The drain plug

instructions can be found on

shotimes.com.

Assembly is pretty much in reverse order,

however

there are a few tricks

of the trade that help to make things easier. I'll try to get

a write up on that on

another day.

|

|

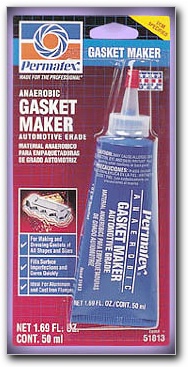

Oh......and one more

thing.

When you seal the case back up NEVER,

NEVER, NEVER,

NEVER

use RTV.......it'll come back to haunt you.

Use

Permatex Anaerobic sealant ONLY!

(Blue

tube, red sealant.)

|

Good

luck!

|